1000+

Professional staff

Professional staff

production line

Factory area

Checked

![[Automotive Tempered Glass Solutions Provider]](https://icdn.tradew.com/file/202410/1576316/jpg/8343425.jpg)

FELIX GLASS As a certified IATF 16949:2016 manufacturer, High-Impact Tempered Glass for New Energy Vehicle Dashboards - HD, Anti-Scratch, UV Protection, we deliver precision-engineered tempered glass solutions for next-gen EV dashboards,central control screens, and in-vehicle systems. Our certification-driven approach ensures compliance with automotive OEM standards.

![[Medical Grade Tempered Glass Cover Solution]](https://icdn.tradew.com/file/202410/1576316/jpg/8343437.jpg)

![[Medical Grade Tempered Glass Cover Solution]](https://icdn.tradew.com/file/202410/1576316/jpg/8209139.jpg)

As a leading custom tempered glass cover manufacturer, FELIX GLASS provides custom tempered glass covers for LCD screen protection, as well as FDA/CE certified custom tempered glass for portable ultrasound systems, which are ultra-thin, drop-proof, and disinfection-resistant. We specialize in providing precision engineering solutions that meet the stringent requirements of the global medical industry. Our products excel in critical medical environments with the following key advantages

![[Solar Control System Glass Panel]](https://icdn.tradew.com/file/202410/1576316/jpg/8209140.jpg)

As a leading global manufacturer of custom tempered glass panels, we focus on providing customized high-performance solutions for key applications such as solar photovoltaic controllers, household solar systems, energy storage devices, portable mobile power supplies and photovoltaic energy storage systems. Our tempered glass panels use cutting-edge technology and meet strict safety standards to protect LCD screens in these harsh environments.

![[Charging Station Customized Glass Solutions]](https://icdn.tradew.com/file/202410/1576316/jpg/8343446.jpg)

![[Charging Station Customized Glass Solutions]](https://icdn.tradew.com/file/202410/1576316/jpg/8209141.jpg)

As an IATF 16949 certified automotive grade tempered glass manufacturer, we focus on providing high-performance solutions for electric vehicle charging station displays, combining advanced engineering technology with strict quality control. Our glass panels are carefully designed to meet the rigorous requirements of outdoor environments, ensuring durability, safety and user-friendly operation experience.

![[Smart Switch Glass Panel Solution]](https://icdn.tradew.com/file/202410/1576316/jpg/8343492.jpg)

![[Smart Switch Glass Panel Solution]](https://icdn.tradew.com/file/202410/1576316/jpg/8209142.jpg)

[Smart Switch Glass Panel Solution]

9H Scratch Resistant Tempered Glass Panel for 86mm Smart Touch Light Switch - Aluminosilicate Glass with 3M VHB Tape

Invisible Protection, Superior Control For smart switch manufacturers and system integrators designing high-end home automation, hotel controls and commercial panels,Our carefully crafted glass panels last 3x longer than standard panels (proven over 500,000 touches).

![[Customized Glass Manufacturing Solutions]](https://icdn.tradew.com/file/202410/1576316/jpg/8343700.jpg)

![[Customized Glass Manufacturing Solutions]](https://icdn.tradew.com/file/202410/1576316/jpg/8209143.jpg)

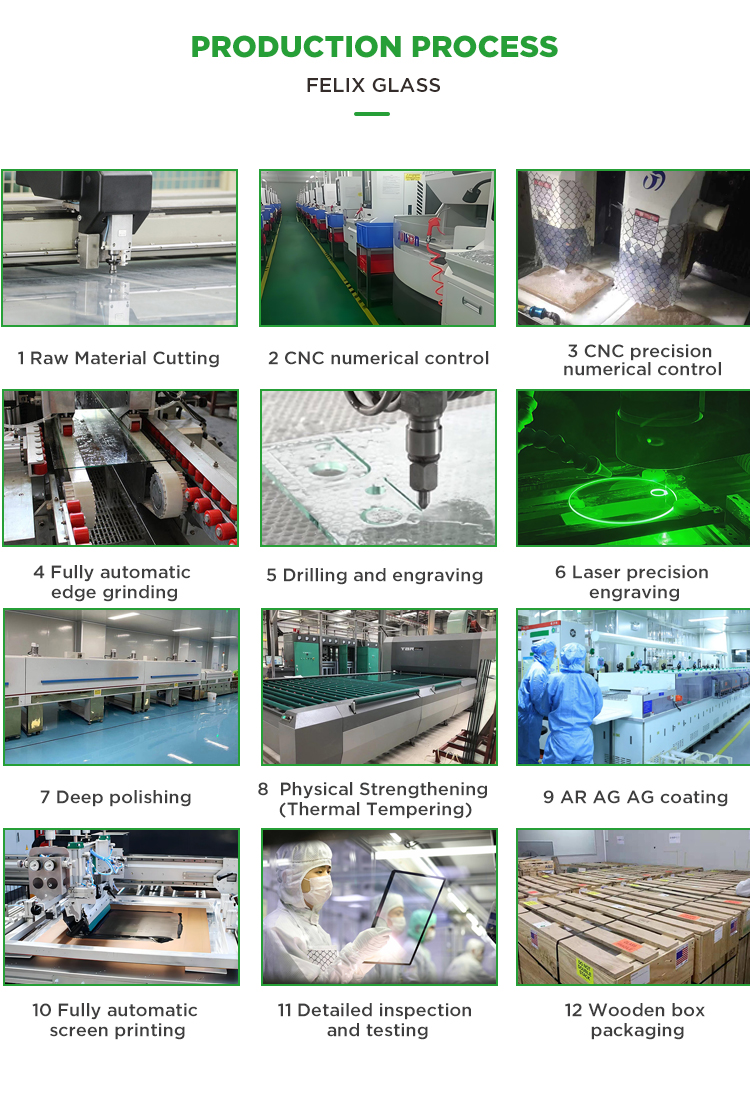

We have advanced glass manufacturing facilities: CNC/laser cutting and edge polishing, precision CNC machining, glass laser cutting, fully automatic hot bending machine and flip polishing equipment, precision milling countersunk holes and blind holes, precision edge molding, multi-level step surface processing, complex curved glass molding, to meet the strict design requirements of customized glass panel applications from consumer electronics to medical/industrial fields.

100% high-quality raw material inspection to prevent unqualified materials from entering!

100% pre-production sample confirmation to reassure every customer!

100% production process detail inspection to ensure that every process is refined!

100% pre-shipment inspection to ensure that every product satisfies customers!

Our minimum order quantity is:

10 pieces of existing optical glass/display glass/glass products

100 pieces of screen-printed brand logo

500 pieces of more complex custom glass

1000 pieces of unique molds

FELIX GLASS has four self-operated R&D and production base factories, and one glass raw material factory, and has invested in an international logistics company to provide customers with the ultimate product experience and international transportation price cost.

FELIX GLASS has more than 1,100 fully automatic customized glass deep processing production machines and testing equipment, and 105 R&D designers and engineers with more than ten years of experience, providing you with the ultimate glass deep processing customization and extremely fast proofing production experience

FELIX GLASS has a rich variety of well-known brands of ultra-high-quality glass raw materials to choose from, as well as a rich variety of UV-resistant and high-temperature-resistant imported ink screen printing effects, allowing your products to be sold worldwide, and a real experience of zero after-sales service in the field of glass use

FELIX GLASS provides personalized responses to all customer inquiries, ensuring a seamless and efficient experience from consultation to delivery. Quick response time: within 1 minute, quick quotation time: within 1 hour

Fast delivery within 1-15 days depending on quantity

Help you seize more market share

If complex process molds are deeply customized and proofed, fast delivery within 3 days

Batch production delivery within 15-25 days

All FELIX GLASS products have passed ROHS and CE certifications, and the factory production has passed ISO9001 and SGS certifications

Of course! We can customize the process according to your needs: shape cutting, AR AG coating, high temperature oven, polishing and tempering, anti-UV ink printing, based on our mature supply system for processing and customization

Since customized samples and shipping costs are high for both parties, in order to ensure a win-win situation for both parties and quality assurance, we only provide high-quality samples. But we can also provide existing product renderings and design mold services. Usually, we will first provide product renderings with your LOGO as a reference. Click to learn more about free samples

The minimum order quantity for our factory production is flexible and negotiable. Usually the MOQ is 100 pieces, and lower quantity is acceptable for trial order. Please feel free to let us know the quantity you need.